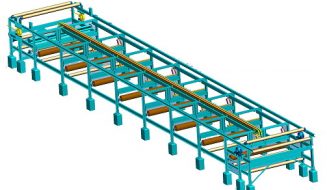

Horizontal Vacuum Belt Filter

The EIMCO-K.C.P. Horizontal Vacuum Belt Filter has most of the operating capability of a bottom pickup vacuum filter… additionally, it has the operating flexibility to meet particular processing requirements some unique and exclusive capabilities – Simplicity of operation, and fluctuations, the ability to handle feed with low and high solids concentrations, and highly effective cake washing for increased product recoveries and profitability.

EIMCO-K.C.P. offers the most reliable and efficient horizontal belt filters in the field. The designed system is applied for the separation of liquids and solids in various fields as listed below.

WIDEST APPLICATIONS IN THE FIELD OF:

- Coal, Iron ore, Lead, Copper, zinc, Nickel, etc.

- Flue Gas Desulphurization

- FGD washing of gypsum cake

- Pyrite

- Magnetite

- Phosphate Rock

- Chemical Processing

COSTRUCTIONAL FEATURES AND BENEFITS

- EIMCO-K.C.P. filters are available from 5 sqm to 200 sqm with belt sizes range from 0.2 m wide to 4.2 m wide of belt width. The belts are imported as factory vulcanized (endless) from reputed suppliers from Europe.

- Rigid structural main frames and cross frames with higher load carrying capacity

- German Planetary drive with variable frequency speed drives, offering speed range up to 30 meters per minute.

- Head pulley and tail pulleys with rubber covered, grooved to provide prevention of belt slippage. Shaft ends with suitable material is offered according to the process.

- Standard pulley bearings from reputed makes of SKF / FAG for the pulleys and rollers.

- Belt support deck with air float as standard feature. Optional systems of roller design / slide rails are provided.

- Vacuum pans designed to provide high liquid handling with material suitable to process.

- For maintenance air operated lowering mechanism of pan is provided with ample space for wear belt change.

- In house Manufacturing capability with Assured quality, certified ISO 9001 company.

FEATURES OF EIMCO KCP HBF

- Higher Filtration rates with minimum moisture content.

- Lower operating and maintenance costs due to efficient & sturdy design.

- Low friction advanced air box mother belt support system, Variants can be offered with slide rails or roller decks support system.

- Controlled belt aligning systems results in maintenance free running for a long time.

- Multi stage washing.

- Longer life of mother belt due to less friction of air box support.

- Drier filter cake output.

- As the length and process time of each belt filter is configured to suit the application for which it are intended, superior results can be achieved.

TESTING & SIZING TO ENSURE THE END RESULT

EIMCO-K.C.P. with the expertise of more than 45 years of field experience offers accurate, reliable bench scale and pilot test works to make sure predictable behavior of slurry in the field.