Drive Heads

THICKENER / CLARIFIER DRIVE HEADS

Hydraulic & Mechanical Drives.

The drive head is the heart of the Thickener & Clarifier mechanism. The present design of The EIMCO-K.C.P. Drive heads is a result of careful study and experience gained over 50 years of operation in the Sedimentation Equipments operating in various Mineral Industries, Chemical Industries, Water Treatment Plants, Sewage and Effluent Treatment Plants under severe operating conditions.

A Sedimentation drive generally operates at a relatively low value of output torque in a well-operated installation. As long as the solids input equals the solids output from the mechanism, torque will begin to climb and the alarm on the drive control will actuate to warm the operator to take corrective action.

Three types of drives are generally used for Clarifier and Thickener Mechanism. “W” Series / “B” Series / “C” Series

The drive head torques up to 4,600,000 ft-lbs.

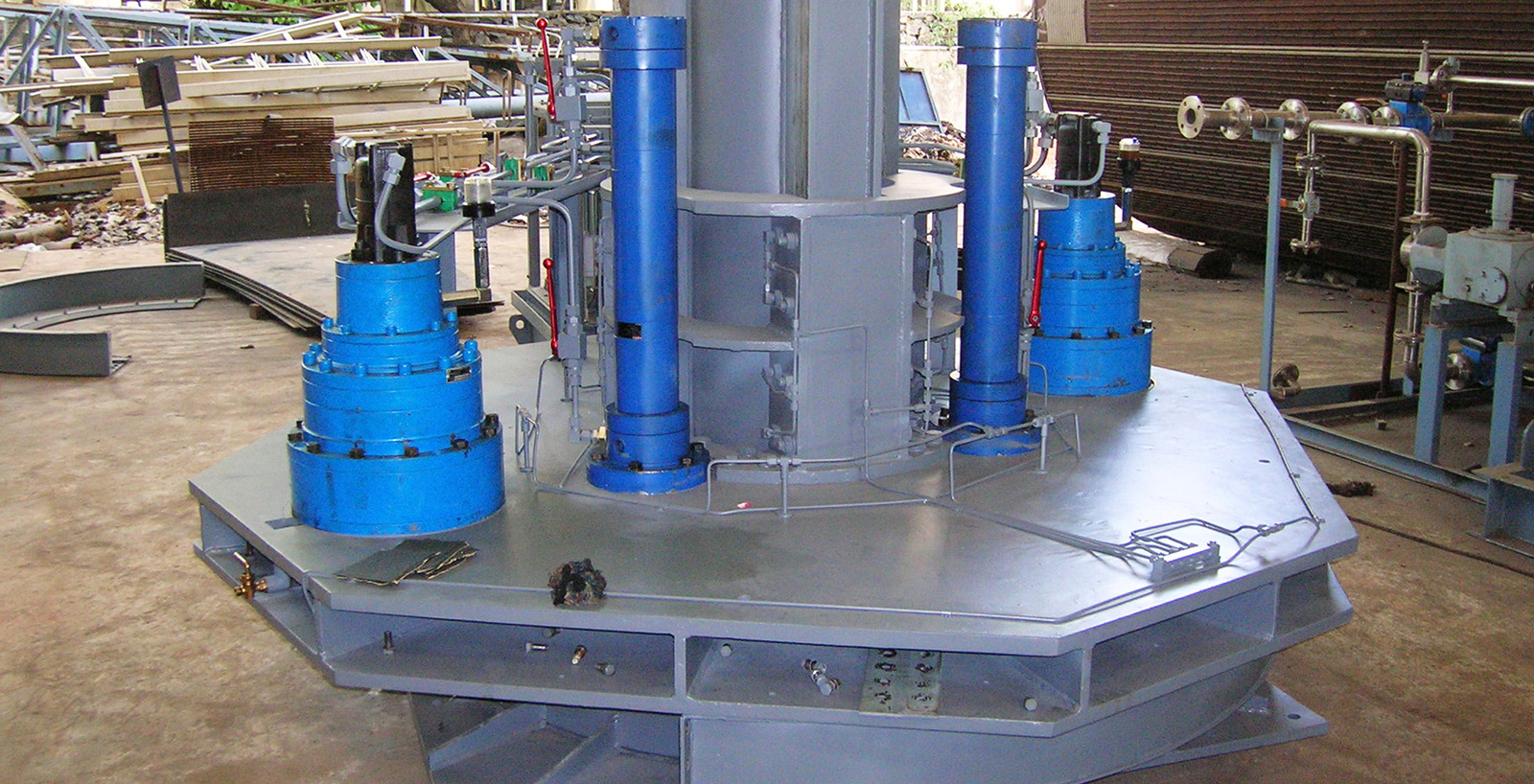

Hydraulic Drive Heads

The EIMCO-K.C.P. Hydraulic Drive includes drive unit with bull gear and pinion driven by planetary gear system intern by a hydraulic motor, by a hydraulic power pack. Also the unit includes a torque transducer to activate the overload alarm and to produce an output signal. Automatic rake lifting arrangement and drive tripping arrangement is provided in order to protect the mechanism from overloading.

- The drive is mounted on a lift plate and provided with hydraulic lift arrangement with cylinders.

- Drive Heads with duty rated torque up to 4,600,000 ft-lb’s and peak torque rating up to 13,800,000 ft-lb’s using High Precision Ring Gears are standard on large EKCP Thickeners

- Increased torque capacity.

- Reliable and adjustable torque sensing.

- Hydraulic drive heads are offered for both ‘B’ Type and ‘C’ Type Thickeners.

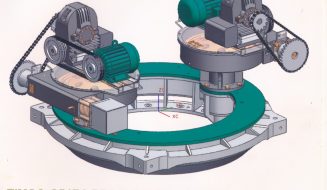

Mechanical Drive Heads

- Spur gear drives, utilized in center column mounted operation, are manufactured with heat-treated cast steel main spur gears, alloy steel pinions, alloy bronze worm gears and hardened steel worms. These are mounted on precision bearings and enclosed by dust tight cast iron housings for oil lubrication. The drives provided with slew ring bearing to withstand high load.

- For bridge-mounted operations, the drive units are manufactured with heat-treated cast steel main spur gears, alloy steel pinions, alloy bronze worm gears and hardened steel worms; all mounted on precision bearings and enclosed by dust tight cast iron housing for lubrication.

- Worm gear drives for smaller units have high quality cast iron main gears with hardened steel worms; mounted on precision ball bearings and enclosed by dust tight cast iron housing for lubrication.