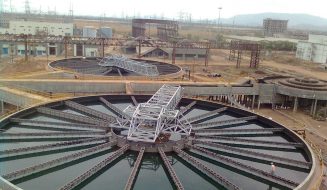

High Rate Solids Contact Clarifier

Reactor Clarifier solids contact units allow several different design configurations (varying flocculation distribution, recirculation rates and rake torques) meeting even the most exacting standards for quality.

THE EIMCO-K.C.P. LTD Solids Contact Reactor Clarifiers are basically divided into two different classes HRC and HRB mechanisms.

HRC is the high rate column supported Reactor Clarifier of size ranging from 15m to 75m diameters. HRB is a high rate bridge mounted Reactor Clarifier supplied in sizes ranging from 3m to 25m diameters.

- The high rate Solids-Contact Reactor Clarifier operates with the raw influent liquid being brought into immediate contact with a large circulating volume of relatively dense previously formed flocculate and precipitate.

- The mixture of raw influent liquid and re circulated slurry is sent upward into the reaction cone with 75-90% being returned to recirculation with the incoming raw water.

- The remaining 10-25 % passes under the cone and into the clarification zone. Once in the clarification zone, the solids settle to the tank floor with the clarified liquid moving into the effluent launder and exiting tank

The BFR and CF Reactor Clarifiers are applied to processes where longer detention times within the feed well and no solids recycle are necessary or requested by customer. The detention times are considerably longer than those offered by higher rate solids-contact units and are necessary for proper flocculation.